Energy storage for marine applications

Powering the marine industry

for a net-zero future

Skeleton's SuperBatteries offer industry-leading performance:

- Designed for 50,000 life cycles

- Excellent safety and reliability

- Maximum power and energy performance up to 120C dedicated for high charging/discharging cycles

- Scalable battery pack from kWh to MWh

The combination of SuperBattery energy storage and Skeleton's agile and large engineering teams and software development expertise are a proven advantage for our customers in the marine sector, looking to find ways to align with environmental regulations.

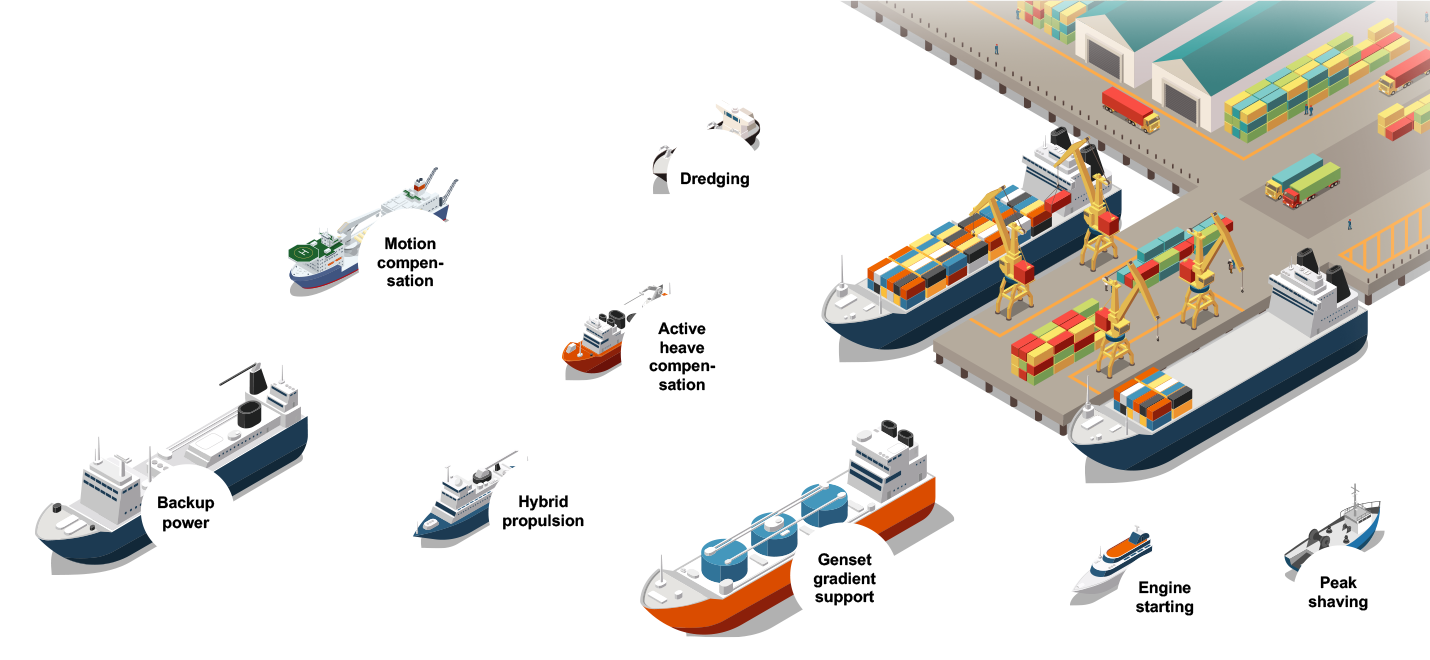

SuperBatteries offer a clear advantage in a number of applications: backup power, peak shaving, spinning reserve, active heave compensation, blackout prevention, zero emissions and maneuvering in port, load leveling, and hybrid or electric ferries.

"Our customers in the marine industry appreciate the speed and agility of our engineering teams. Close cooperation in development with our customers is key for us. "

SuperBattery-based energy storage solutions

for high power marine applications

SuperBatteries provide a reliable and fail-safe power supply for marine vessels in the event of a main power loss, allowing critical equipment to remain operational. This back-up power solution provides peace of mind and ensures smooth, uninterrupted operations even in the most extreme conditions.

SuperBatteries can be used to shave peak power for ships, providing increased stability on the ship's grid and improved power supply while minimizing wear and tear on generators due to reduced mechanical stress. This helps keep ships running smoothly and efficiently for longer periods of time.

SuperBatteries are more competitive and reliable than pneumatic accumulators when it comes to recovering energy and providing peak power to motion compensated pile grippers and similar marine heavy equipment. While ensuring vertical stability of the crane payload in offshore operations, SuperBattery-based energy storage systems are the best technology to save fuel and improved power control in bad sea conditions

Parallel hybrid propulsion with SuperBatteries for ships offers improved fuel savings and reduced mechanical wear on the propeller drive train. This hybrid propulsion solution helps to increase efficiency and improve the longevity of vessels over time.

SuperBattery-based energy storage solutions

for marine applications

The use of a SuperBattery for ships to provide spinning reserve eliminates the need for additional generators, while operating gensets at optimal load helps reduce fuel consumption. This is an effective way to achieve redundancy and save costs at the same time.

By employing a SuperBattery to support engines, ships can maintain grid stability with quick load response. This energy storage solution can also help save costs and improve efficiency.

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Unfortunately, we can't service private customers - thank you for understanding. If you are curious about using ultracapacitors at home, please have a look at our blog post Ultracapacitors vs. Batteries for more information.

Enter your information below for our team to contact you.