Heavy transportation

Powering heavy

transportation for a

net-zero future.

Skeleton's supercapacitor and SuperBattery solutions enable electrification of transportation, eliminate downtime, and help cut fuel consumption

"Skeleton’s development work on the supercapacitor pack provides our system the power and reliability for constant operation."

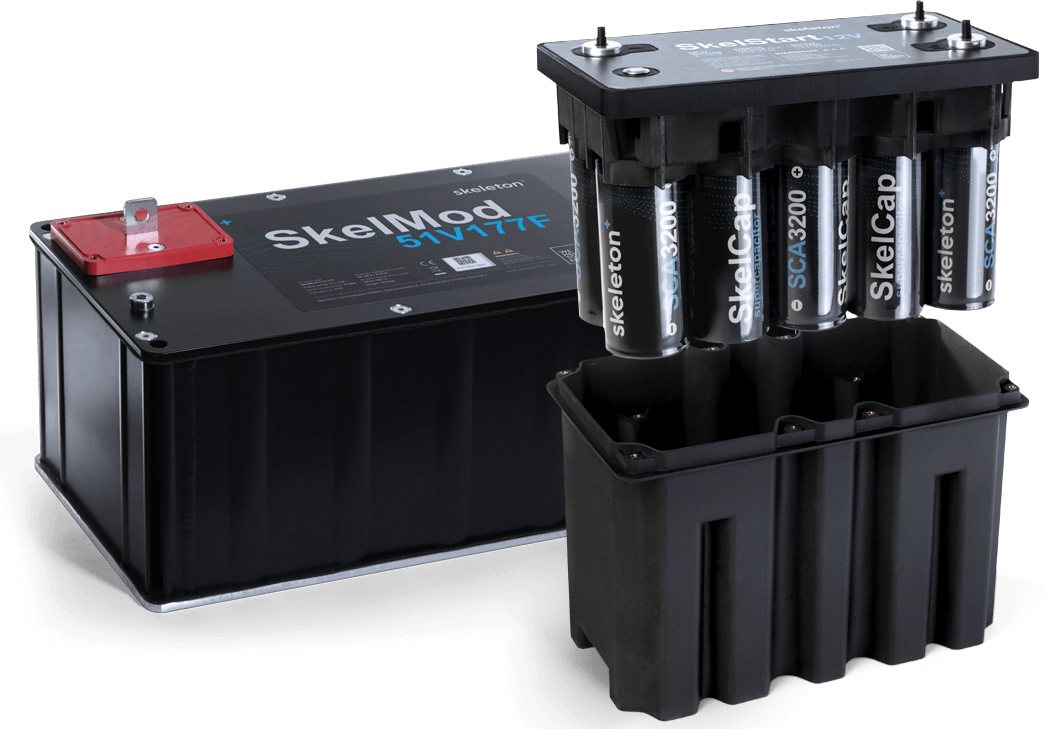

Micro Hybrid solutions

for truck industry

Truck Start-Stop: 5-15% lower total fuel consumption

Engine start even in extreme weather conditions: Full power performance from -40°C to +65°C

Upcoming regulation changes: lead-acid battery ban and emission restrictions

Mild Hybrid solutions

for truck industry

Service cost reduction (CAPEX and OPEX)

Improved fuel efficiency and reduced CO2 emissions

Longer life & zero maintenance

Increased safety

Full electric solutions

for truck industry

Most cost-effective solution for high utilization scenarios

Enable regenerative braking: maximum motor power

EU regulatory compliance: No CO2 emissions

The extremely high current tolerance of SkelCap is crucial in heavy-duty drivetrains.”

Tero Järveläinen

R&D Manager

Visedo Oy

Visedo Oy

Hydrogen solutions

for truck industry

Quick response time and boost: supercapacitors are the key enabling technology for Fuel Cells

Li-ion battery pack needs to be oversized to cater for peak loads

Increased safety with zero maintenance

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Unfortunately, we can't service private customers - thank you for understanding. If you are curious about using ultracapacitors at home, please have a look at our blog post Ultracapacitors vs. Batteries for more information.

TRUSTED BY

Enter your information below for our team to contact you.