Curved Graphene - innovation in energy storage

The power of

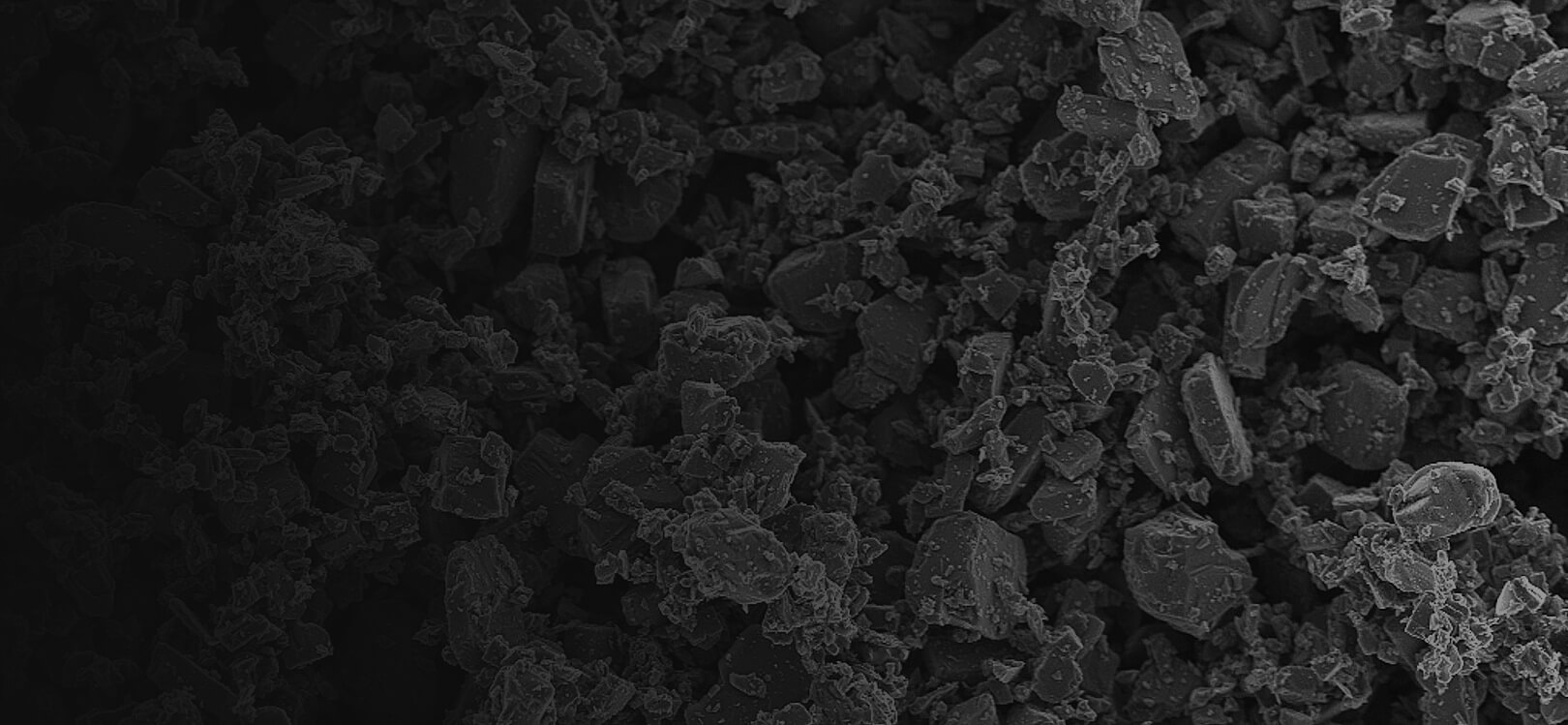

Curved Graphene

Skeleton Technologies Group encompasses the entire value chain for energy storage, from raw materials to storage systems. Based in Bitterfeld-Wolfen, Germany, our fully-owned subsidiary, Skeleton Materials (formerly Black Magic GmbH), specializes in the development and production of Curved Graphene. This novel synthetic carbide-based carbon material significantly enhances the energy density of supercapacitors.

The battery industry is actively seeking sustainable substitutes for critical raw materials like nickel and cobalt to ensure Europe’s security of supply. Curved Graphene delivers unparalleled performance levels without the need for toxic or rare metals. It enhances electrode functionality using locally sourced materials which are widely accessible and abundant in Europe. This significantly reduces our dependence on non-European metals crucial for decarbonizing the continent.

Material Innovation

Material development is the cornerstone of our strategy. Unlike other key players in the battery industry who primarily compete in engineering with the same raw materials, Skeleton Technologies has adopted the strategy of vertical integration. This approach encompasses the entire value chain, from the microporous carbon material to cells, modules, and systems, including advanced control algorithms and software.

Curved Graphene, a recognized key innovation, helps industries cut fossil fuel reliance and advance in net zero journey. Our scientists Jaan Leis, Mati Arulepp, and Anti Perkson were honored with the European Inventor Award 2022 by the European Patent Office for their groundbreaking work in optimizing Curved Graphene, achieving exceptional power and energy density in supercapacitors. Additionally, Skeleton Materials received accolades at the German Hugo Junkers Awards for Research and Innovation in 2019.

Characteristics

From a technical perspective, Curved Graphene allows for customization in the ratio of micro- to mesopores based on specific application requirements. In supercapacitors, where energy storage predominantly occurs in micropores, a substantial micropore surface area is essential. While optimized activated carbons typically achieve a micropore ratio between 0.5 and 0.6, Curved Graphene can reach up to 0.95, maximizing capacitive energy storage.

Trying to find most

cost effective solution

for your system?

Discover how our solutions can power your success.

The production process of Curved Graphene is protected by several patent families worldwide. In synthesizing Curved Graphene, we utilize our patented fluidized bed reactor (FBR) technology. This advanced technology supersedes traditional rotary kiln reactors, which limit gas and solid interaction due to mechanical constraints. In contrast, our FBR technology fluidizes a bed of particles with a gas stream, creating a liquid-like movement of solids and allowing for more efficient reactions.

We aim to expand Curved Graphene production in 2025 to broaden the material’s availability and harness its full potential.

Saving energy has

never been more important

Taavi Madiberk,

CEO of Skeleton