Fast Engine Start

In All Conditions

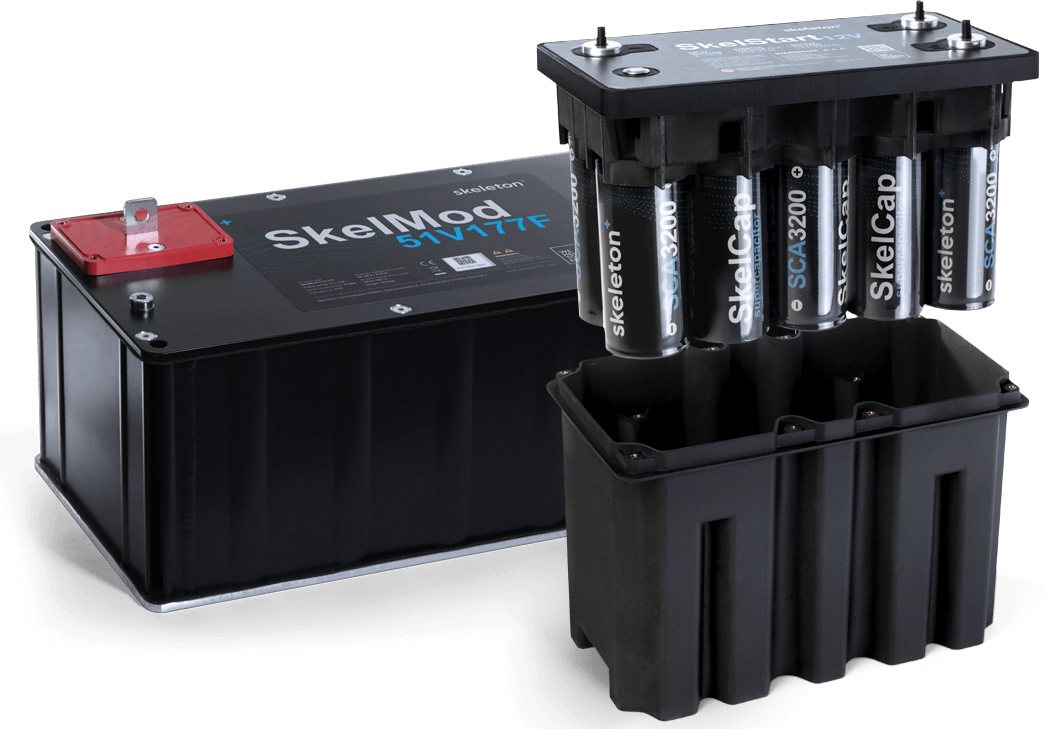

Eliminate downtime and cut fuel consumption with Skeleton's high power energy storage solutions.

Reliable Engine Start in All Conditions

Full power performance in -40°C to +65°C

Reliable power in extreme conditions

- Consistent performance from -40°C to +65°C, ensuring smooth operations in diverse climates.

- Engine starts even in severe weather, preventing downtime.

Temperature

-40°C to +65°C (149°F)

Quick Power Boosts for Demanding Applications

- Supercapacitors ensure quick response times, boosting fuel cells for peak loads.

- Li-ion battery packs can handle power surges when oversized for peak demands.

Up to 5% Lower Fuel Consumption

Having a reliable engine start in all conditions eliminates the need to keep the engine running overnight, enhancing fuel efficiency

- Reduce fuel consumption by up to 5% using truck start-stop technology.

- Improved fuel efficiency lowers operational costs and CO₂ emissions.

Temperature

-40°C to +65°C (149°F)

Bypass Lead-acid battery bans

- Designed to meet lead-acid battery bans and new emission restrictions.

- Fully electric solutions ensure no CO₂ emissions, aligning with EU mandates.

Durable With Zero Maintenance

- Longer component life spans with zero maintenance reduce CAPEX and OPEX.

- Increased safety standards for trucks and drivers.

Cost-Effective High-Performance Solutions

- Full electric options are ideal for high-utilization scenarios, ensuring cost savings.

- Regenerative braking enhances energy recovery and maximizes motor power.

"Skeleton’s development work on the supercapacitor pack provides our system the power and reliability for constant operation."

Quality is the bedrock of Skeleton. We have put an enormous amount of work in to producing the most robust and long-lasting products for our customers.”

Dr. Linus Froböse

CTO

Skeleton Technologies

Skeleton Technologies

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Unfortunately, we can't service private customers - thank you for understanding. If you are curious about using ultracapacitors at home, please have a look at our blog post Ultracapacitors vs. Batteries for more information.

TRUSTED BY

Enter your information below for our team to contact you.