Stabilize

Highly Stressed Automotive 12V Boardnets

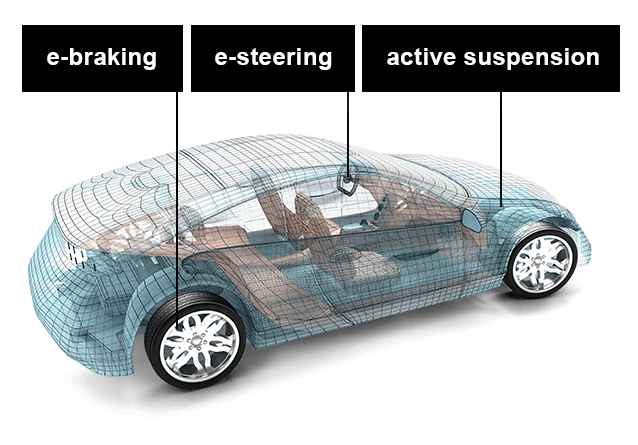

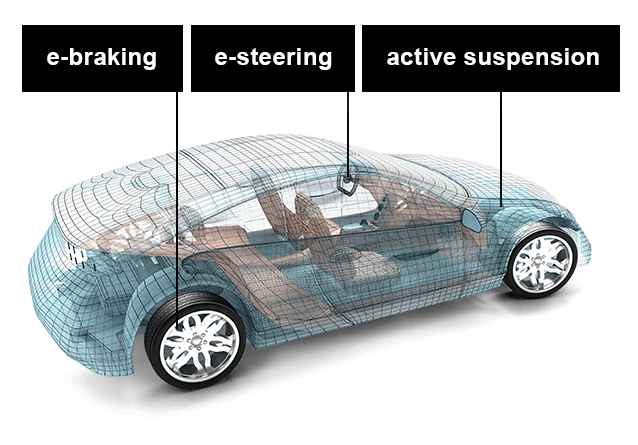

Electrified safety and autonomous functions such as e-braking, e-steering and image/LIDAR analysis computing require increased power.

- Break & Steer by wire.

- Active suspension.

- Energy recuperation from breaking.

The Largest OEMs

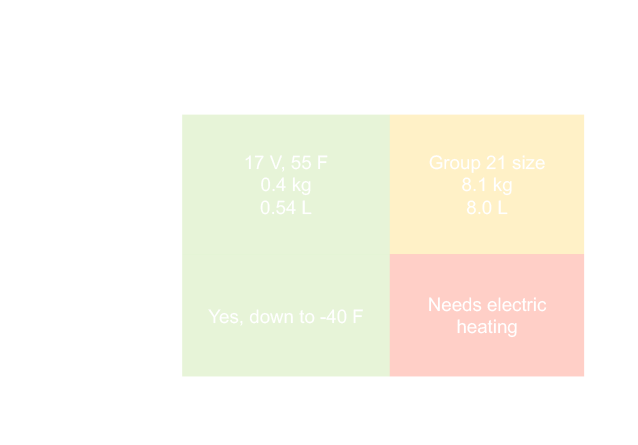

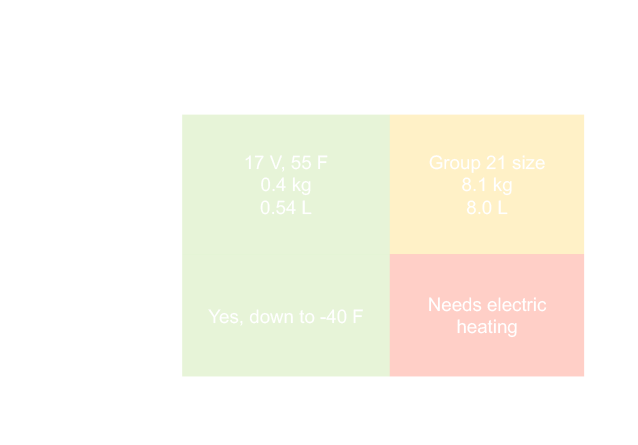

Autonomous functions require the 12V on-board-net to perform well in “worst-case” scenarios, such as low state of charge combined with low temperature. Simultaneously, power requirements are rising. Skeleton's products operate in:

- Extreme temperatures (-40° to 65°C/149°F).

- Highest power in the market.

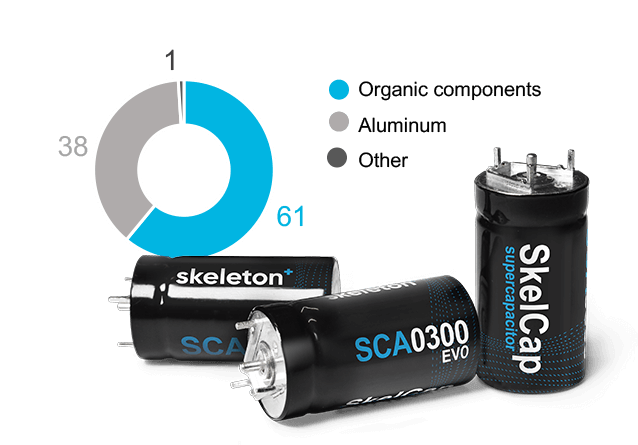

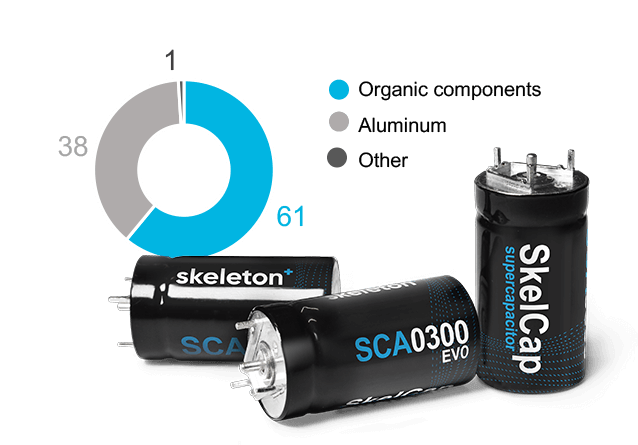

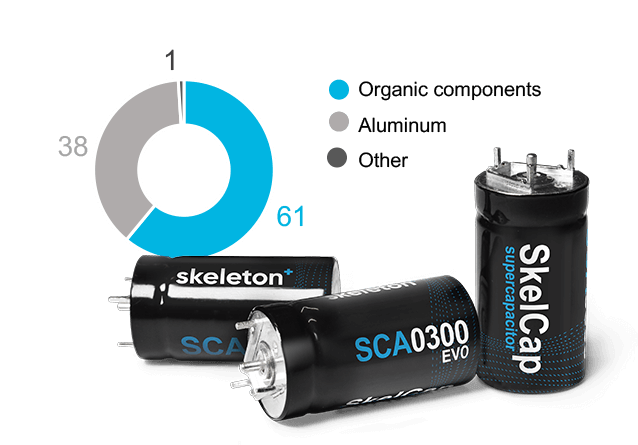

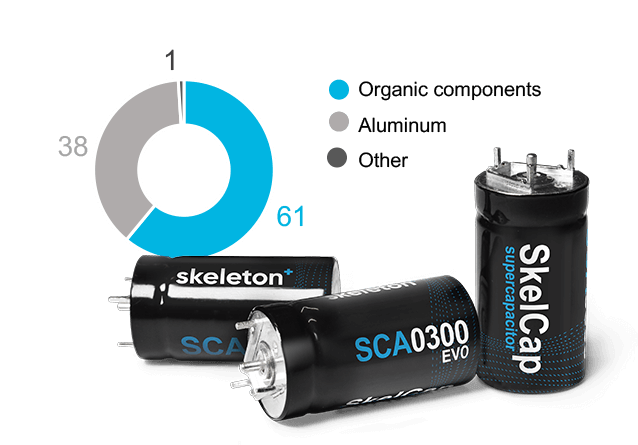

Skeleton's Curved Graphene based solutions are inherently safe

- No thermal runway.

- High thermal tolerance.

- Safe even when pierced, crushed, or overheated, due to no lithiated graphite or lithium plating.

- No reliance on rare or hazardous materials.

- Supports a greener, more sustainable energy ecosystem.

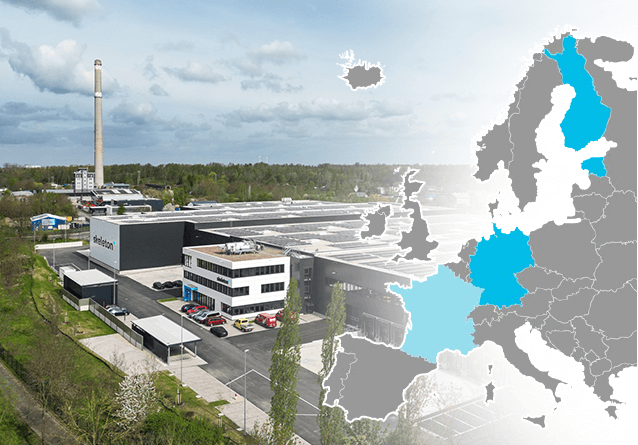

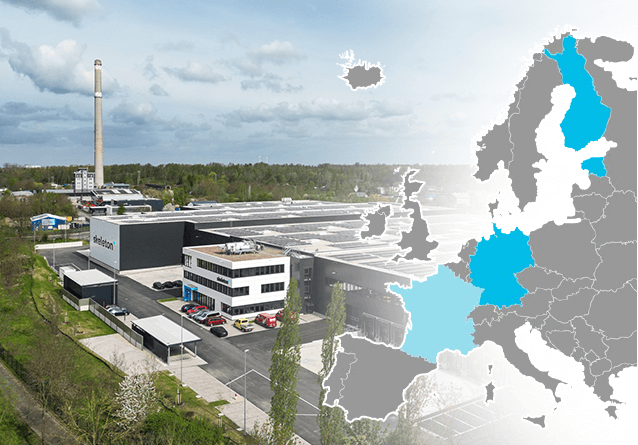

- Designed and produced in the EU.

New European battery directive (regulation concerning batteries and waste batteries) will impact both lead-acid and Lithium-ion batteries. Batteries heavier than 5 kg will be treated as “industrial batteries” and face added regulation on recycling and sustainability.

- Free from cobalt, lithium, and rare earth minerals.

- Braking energy recuperation.

- Acceleration of heavy cars.

For FCEVs and HEVs, the battery size is < 2kWh, but the power rating is >100 kW, requiring >50C charge/discharge rate.

A high number of daily cycles decreases Lithium-Ion battery lifetime.

"Using Skeleton's advanced supercapacitor technology, we have been able to test out something novel and unique, which is what racing is for."

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Unfortunately, we can't service private customers - thank you for understanding. If you are curious about using ultracapacitors at home, please have a look at our blog post Ultracapacitors vs. Batteries for more information.

Enter your information below for our team to contact you.