Energy storage for rail applications

Powering the rail industry

for a net-zero future.

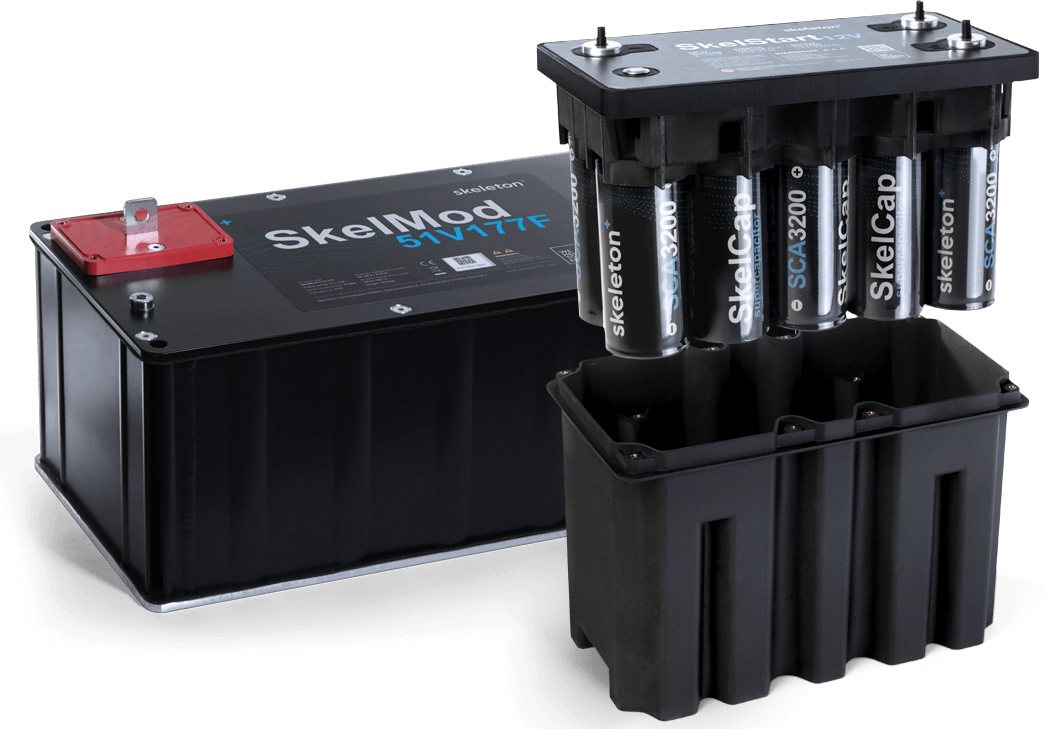

Supercapacitors can help electrify the rail industry with supercapacitor energy storage

"Skeleton’s development work on the supercapacitor pack provides our system the power and reliability for constant operation."

Hybrid and KERS solutions

for rail industry

Increased utilization of the train even in congested & polluted areas

Service cost reduction (CAPEX and OPEX)

Improved fuel efficiency and reduced CO2 emissions

Wayside Energy Storage solutions

for rail industry

Increased energy efficiency and longer lifetime of the wayside system

Up to 20% energy cost reduction

Catenary supply peak load reduced

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Unfortunately, we can't service private customers - thank you for understanding. If you are curious about using ultracapacitors at home, please have a look at our blog post Ultracapacitors vs. Batteries for more information.

TRUSTED BY

Enter your information below for our team to contact you.