Ultracapacitor technology

Award-winning

energy storage

technology

solutions for electrification

Your cells have very low resistance so are truly high-power devices. I think they are the best in the world of the carbon/carbon type.”

UCDavis, University Center on Sustainable Transportation

What are ultracapacitors?

Ultracapacitors or supercapacitors are an energy storage technology that offers high power density, almost instant charging and discharging, high reliability, extreme temperature tolerance, and lifetimes of more than 1,000,000 charge-discharge cycles.

Ultracapacitors have been in development for decades, but the biggest development steps have happened only in the past 15 years, driven by advances in nanomaterials with Skeleton's Curved Graphene being a prime example of a breakthrough technology.

Ultracapacitors are now delivering significant economic benefits in the form of energy and fuel savings across a wide range of markets including automotive, grid and renewable energy, transportation, and industrial applications.

- 4x power density compared to competitors

- High power (up to 60x compared to batteries)

- 1,000,000+ lifecycles

- Ultrafast charging times (<1 s)

- +72% increase in energy density (16 Wh/L), while maintaining high power

- 1,000,000+ lifecycles

- Ultrafast charging times (<1 s)

- Increased efficiency & lower footprint

- High energy density (65 Wh/kg)

- 50,000+ lifecycles

- Fast charging times (60s)

- Extremely competitive cost-base compared to similar energy storage technologies

Trying to find most

cost effective solution

for your system?

Discover how our solutions can power your success.

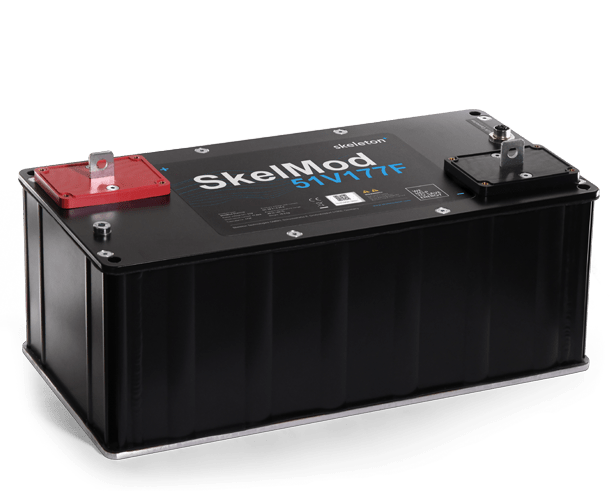

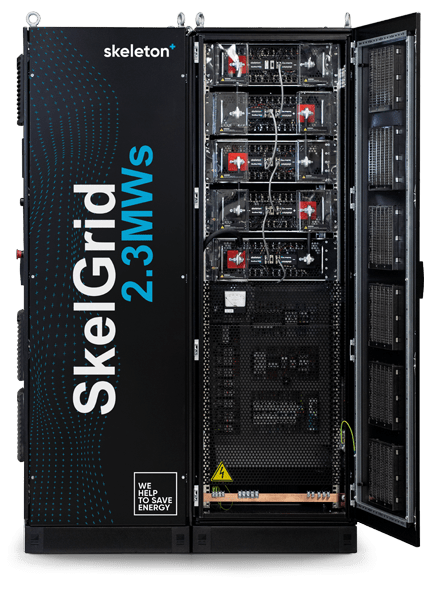

From supercapacitor cells to energy storage systems

Our patented Curved Graphene carbon material provides our supercapacitors with superior power and energy density in the supercapacitor industry, and this advantage carries over to our supercapacitor modules and systems.

We make our own Curved Graphene carbon raw material, and produce our supercapacitor cells, modules, and systems to strict quality standards, servicing our customers in automotive, transportation, grid and renewables, and industry.

German quality from the global technology leader in high-power energy storage.

Saving energy has

never been more important

Taavi Madiberk,

CEO of Skeleton

Ready to become energy storage expert? Join our newsletter!

JOIN TODAY

AND FIND OUT EVEN MORE INTERESTING FACTS ABOUT THE GREAT WORLD OF ENERGY STORAGE

Get in touch

We can help you to find the best solution for your needs

Please fill in the form below and our team will get in touch with you to discuss your needs in more detail.

Enter your information below for our team to contact you.