...And here is how! The e-commerce industry has been growing at an incredible pace since its beginnings in the late 90s, and the demand for internet-sold goods is still on the rise. This, in turn, requires faster and smarter solutions for manufacturing and warehousing management as the competition is fierce with emerging economies taking more and more market share.

Companies such as Amazon, Walmart, Target, and La Redoute, to name a few, have to invent ways to counter low-cost manufacturing and warehousing from emerging economies where different safety and environmental rules and working conditions apply.

![]()

A Skeleton Technologies ultracapacitor pack for shuttles and AGVs.

One of the ways to do this is to increase productivity and reduce headcount in the manufacturing and warehousing sectors. The use of automated machines to produce goods is not a new thing in itself, but the use of automated vehicles to either carry a product or parts of it while it is being manufactured or when it is stocked in a warehouse is gaining momentum and started only recently.

Through the means of in-ground metallic wire, 3D positioning and triangulation, laser guidance, or simply tape on the floor, automated vehicles of various shapes and sizes find their way through the mazes of large production or sorting buildings, being mindful of any people or other vehicles, automated or not, that would come in their way.

Welcome to the world of material handling!

Three categories of automated vehicles

AGVs

![]()

Automated Guided Vehicles, or AGVs, are robots guided by vision, magnets, or lasers for navigation within a warehouse or a manufacturing facility. Ideal for moving materials or packages around, their use is exploding.

AGVs are currently powered by battery packs, which are taken out for recharge in a specific area of the warehouse or factory building. This is time-consuming and takes up valuable space. In some cases, the battery packs are directly replaceable by ultracapacitor packs with a voltage that is allowed to drop from 60 V to 24V during use. Using ultracapacitors instead of batteries, AGVs could be charged in seconds and could operate without fail in cold environments.

Shuttles

![]()

Shuttles are prime candidates for ultracapacitor use. They are used to move pallets and packages within a warehouse storage system.

Using ultracapacitors drastically increases shuttle lifetime and decreases charging time to practically nothing, because with ultracapacitors, shuttles can use opportunity charging in predermined spots along the route and be fully charged in seconds.

Ultracapacitors will also allow shuttles to work in refrigerated or deep freeze environments, something battery powered shuttles struggle to do.

Forklifts

Design improvement and innovation have been a constant drive in the implementation of these devices. They started being powered by diesel and natural gas motors initially and as requirements for a cleaner air at work grew more stringent the diesel-powered devices got banned from enclosed areas. The trend now is to have electrically powered vehicles wherever and whenever possible.

Electrified forklifts powered with ultracapacitors benefit from decreased maintenance need, fast charging, and the possibility to operate efficiently in refrigerated and deep freeze environments

Benefits of electrification

An electric system has a much higher efficiency compared to an internal combustion system. Savings on cost are relatively easy to reap, especially with much simpler power systems and decreased maintenance needs. Li-Ion batteries allow for a shift service with zero emissions inside the factory and this is a step in the right direction.

However, further improvements are possible on recharge time, efficiency, and lifetime of the vehicles. Graphene-based ultracapacitors can have an important role to play in improving all three aspects.

Currently, the systems equipped with batteries need to recharge every 8 to 12 hours and this can take several hours. To speed things up, a battery swap possibility exists, but this can take about 5 to 10 minutes and requires either an operator or has to be fully automatized.

Another option is to use "opportunity charging". This concept requires having a monitoring system on the mobile device deciding that when the battery is at a certain level, it is time to recharge, and then the network equipped with chargers provides a 10 or 15 minutes boost to recharge the mobile device to an acceptable level. This latter concept allows for uninterrupted work from the mobile device

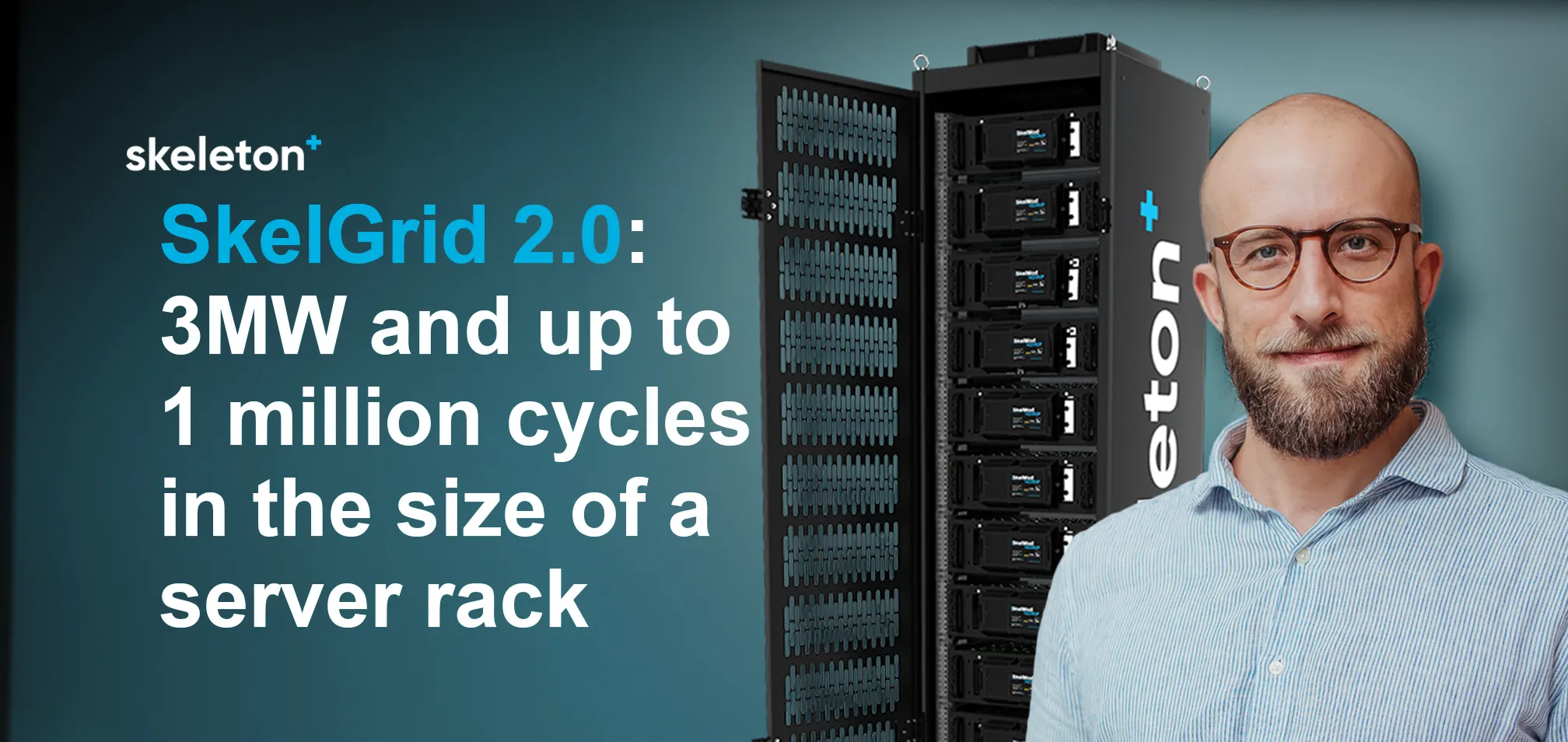

Ultracapacitors are able to charge in seconds. Granted - the duration of their use is limited, but if we take for instance a shuttle moving along a predetermined path repetitively, this can make sense. At the ends of the path and or at predetermined stops, the shuttle can charge its ultracapacitors in seconds and continue its work. Ultracapacitors being able to sustain a million or more charge-discharge cycles will guarantee at least 200 000 hours of use.

This means that instead of requiring 2 shuttles to go around a specific path (1 moving, 1 charging) or having a dedicated space for charging or battery swaps, the need is narrowed down to one single shuttle working around the clock, with practically zero maintenance required on its powering system.

This can be applied to all the other AGVs to an extent, as ultracapacitors can take care of the peak loads when teamed with batteries, and can provide valuable extra uptime between charges whilst preserving the battery lifetime.

It must also be noted that in refrigerated or deep freeze warehouses, battery-operated vehicles may not perform so well, whereas ultracapacitors can perform optimally from -40°C. This not only will increase productivity but also safety at work.