SkelStart Solves Tight Space Allocation Issues on Vehicles

During the design phases of a vehicle, allocated space for systems very often becomes a problem.

The space allocated is determined by the way the structural design is carried out and how it interacts with the outside surfaces.

Very often, the conceptual design starts with a structural frame. This is where the loading actions from the working environment to the structure get taken care of. From this point, the location of the various rigid points, frames, floors, attachment points for powerplants, and locations of driving elements such as driveshafts, wheel axles, and suspension mounts are determined. This defines the primary structure.

Once all of the primary conceptual structural design work is done, the systems need to be integrated, and at this stage, the routes of the various systems are decided. Electrics and electronics, fuel, hydraulics, environmental control, and sanitation lines are routed around the vehicle along where the system components are integrated.

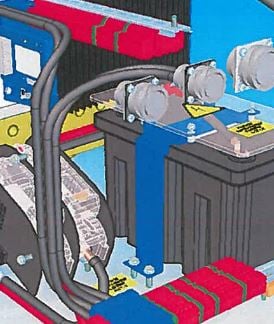

On any vehicle, this needs to fit in allocated spaces and sometimes, for a myriad of reasons, these spaces are either really tight or simply too small for the system components.

It may be possible or necessary to modify the primary structure to allow for the installation of critical equipment, but that is always a costly adventure monetary-wise and in schedule time.

So the less costly alternative is to look for something that can fulfill the role of the system device but can fit in the small bay dedicated to house it.

This is where the Skelstart Engine Start Module comes in handy.

This is where the Skelstart Engine Start Module comes in handy.

The allocated space for the starter pack of the BMU Class 769 flex was too small to fit a lead-acid or Li-Ion battery as a power pack for the ABB Auxiliary Power Supply systems integrated by Brush Traction.

This left them with this kind of quandary:- "Do we heavily modify the design of the prime mover to install the batteries or do we choose to trust the high power density of Skelstart to get these Auxiliary Power Supplies fired up?"

It is a tough call.

On the one hand, you may take a project schedule impact to find a new location and fit a solution that has been there for decades, fulfilling that starting capability with no new design risk, keeping the same maintenance schedule and keeping the risk that at -10°C the APS might have trouble to start.

On the other hand, you integrate a solution that requires some level of testing and that will ultimately be screened by your design experts who will pick every possible bone to make sure it will fulfill its design intent. That solution able to sit on the vehicle for its whole lifetime, requiring no maintenance and able to work right down to -40°C.

Conservatism in design is a safeguard against unforeseen incidents but it can also stifle innovation, and unless the new solution turns out to be very robust with bulletproof reliability, it won't make it past the drawing board.

So, the SkelStart made it through those hurdles and is now a straight fit into the BMU 769s.

Integrators might look at this novel answer to an old problem and increase the reliability of their vehicles by considering replacing starter packs based on batteries by ones that made of ultracaps.

Ultracapacitor starter packs can be designed to deliver 75V voltages for the starter motor of the main engine of the prime mover and perhaps it is time look at how much room, lightness, peace of mind, and safety that solution can add.