AHC System – Keeping Loads Under Control in Harsh Weather Conditions

Safely moving heavy loads from ship to sea floor is a basic requirement in the offshore industry. Typical tasks include the following: pipeline construction and repair, placement of oil and gas wellheads, installing sub-assemblies on drilling rigs or maintenance and repair activities. Similar operations entail dredging, underwater salvage, geotechnical surveys and maintaining offshore wind turbines.

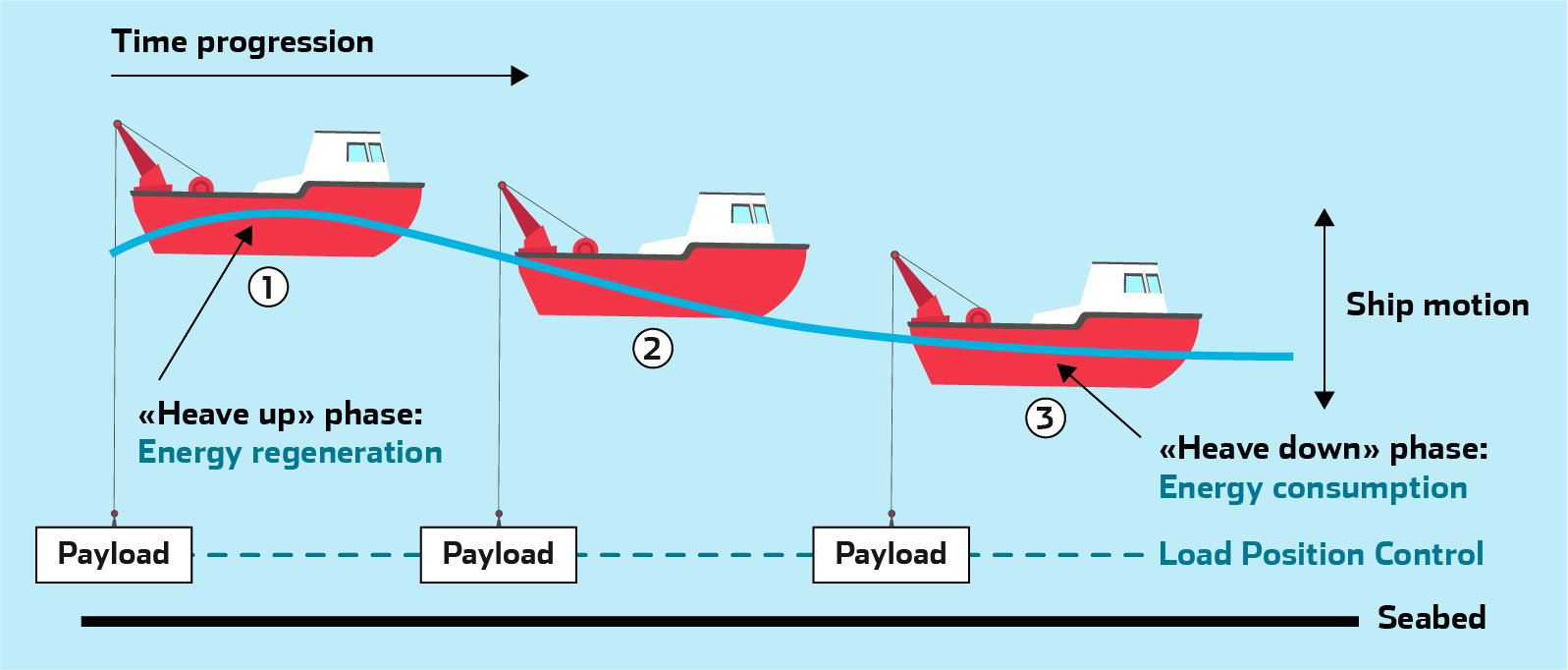

Wave-related ship movements make it difficult to perform these operations and to gently lay a heavy piece of equipment on the bottom of the sea or on another floating vessel. The major risk when working at sea when loading, is that the load acts as a destructive hammer to itself or nearby structures.

AHC - safely moving heavy loads from ship to sea floor

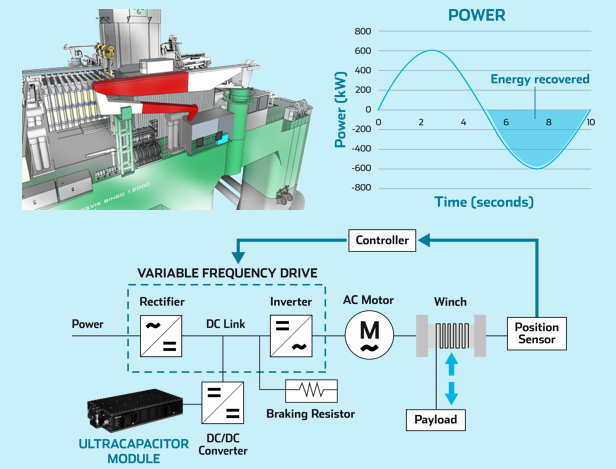

Despite weather conditions, controlled handling of loads is indispensable for safe operation. Hydraulic technologies might be very complex and unreliable, and lead-acid or Lithium-ion battery-powered systems are short-lived. Reliability and safety matter when working at sea, and an ultracapacitor-powered module is a better alternative to batteries. Skeleton Technologies is offering supercapacitor energy storage technology for Active Heave Compensation (AHC) systems, which regenerates energy during the "heave up“ phase and releases it again during the "heave down" phase.

Ultracapacitor energy storage for Active Heave Compensation (AHC) systems

In active heave compensation applications, battery lifetime rarely exceeds a few months. The battery pack sizes become unmanageable because of the power density required to perform the heave compensation function. The active heave compensation system of the future needs to include ultracapacitors.

There are several benefits, which make ultracapacitor- powered systems the best solution for AHC applications:

- Higher reliability and safety when working at sea – the load is stable despite the wave-related ship movements.

- Reduced peak power demand from the generator. When implementing the solution, the power supply split 30% for the genset and 70% for the Energy Storage System. It results in 75% reduction of overall energy demand and considerable downsizing of the genset.

- Reduced power fluctuations – increased efficiency of the overall system, which means more efficient generation and more efficient power consumption.

- No energy losses – energy is being regenerated during the "heave up“ phase and released during the "heave down" phase.

- Longer application lifetime – ultracapacitors can withstand more than 1 million cycles, which guarantees a lifetime of 20+ years for the powering system.

Ultracapacitors have extra low ESR for less dissipation and longer lifetime, they can withstand at least one million cycles, which guarantees a lifetime of 10+ years for the powering system. Their fast response, high power density, and low internal resistance ensure that they will provide the level of power required for the heave compensation system with minimum heat generation and power losses.

The cost of implementing ultracapacitors will also be less than for the implementation of batteries or flywheels because the pack size will be much smaller and not add gyroscopic loads.

If you want to hear more about marine industry applications or you have any questions, get in touch!