Electric machines such as servo presses or simulator test equipment need high power for short durations, but there are challenges:

- High peak loads on the grid connection point

- Heavy load on electrical equipment

- Limits on supplied power from energy providers

These issues, in turn, lead to high demand charge rates and possible fees for grid connection expansion.

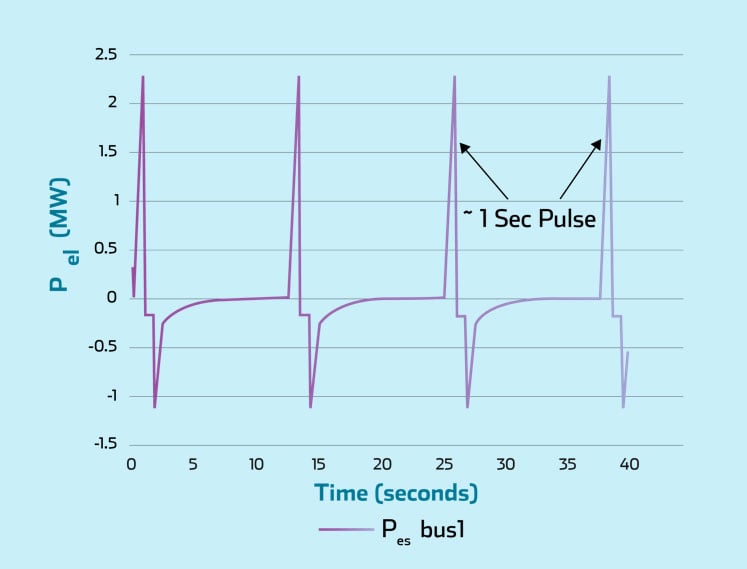

Load profile without ultracapacitors

Skeleton Technologies offers ultracapacitor-based solutions for peak load shaving. The SkelGrid ultracapacitor system is a turnkey solution to reduce peak loads on grid connection points, as well as reducing load on electrical equipment, such as cables, transformers, switches, etc. Lastly, our ultracapacitors have the lowest ESR (internal resistance) on the market, leading to high power efficiency.

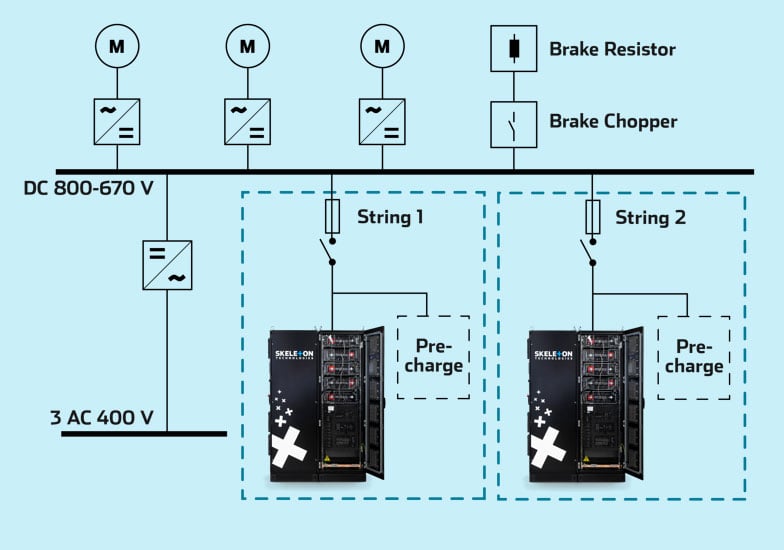

Block diagram of a typical drive system, ultracapacitors directly connected to DC Bus

The benefits of ultracapacitors are clear: reduced peak load on grid connection point, bypassing the limitation in power supply by energy providers, avoiding costs for grid connection point expansion, and reduced demand charge rates based on shaved kWs.

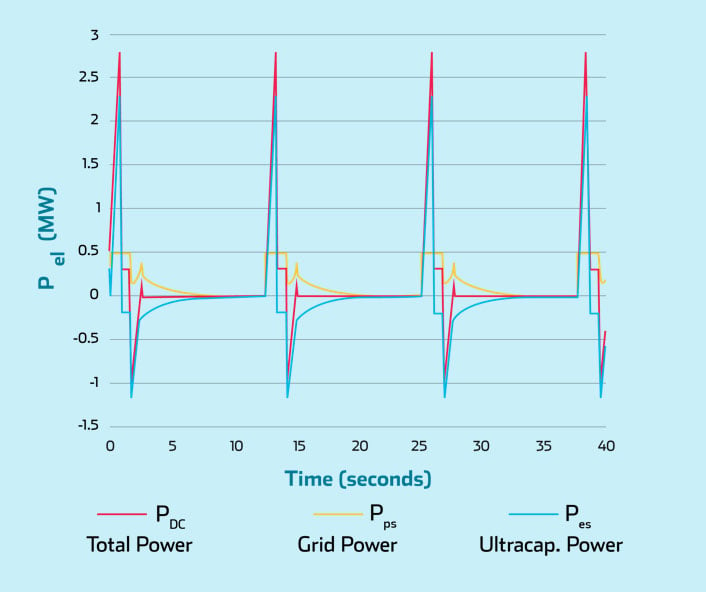

Load profile with ultracapacitors, leading to reduction of peak load by 80-90%

Our ultracapacitors are:

- 100% reliable energy storage with zero maintenance

- Beyond a million cycles & longer calendar life: 20+ years

- Very high power density compared to batteries

- Considerably lighter than batteries in high-power applications

- Easily fully discharged for safe maintenance operations

- Simpler monitoring and system health checks

- Ultracapacitors do not leak or contain acid or lead

CASE STUDY: 82% peak load reduction for simulator test station

For one of our customers, we provided a 9s4p* SkelGrid solution to each DC bus (9s2p as building block) to provide a peak load of 14MW (split to 5 DC busses for different drives) for a large simulator test station.

The result: 82% peak load reduction on grid connection point.