Skeleton's SuperBattery technology has been in the works for years, or rather decades if we look at the development of the Curved Graphene raw material. The need for such technology has become apparent in the past several years with energy storage being the key enabler in electrification, whether it comes to switching from internal combustion engines to electric vehicles, or the increase of renewable energy production replacing traditional coal-based power generation, for example.

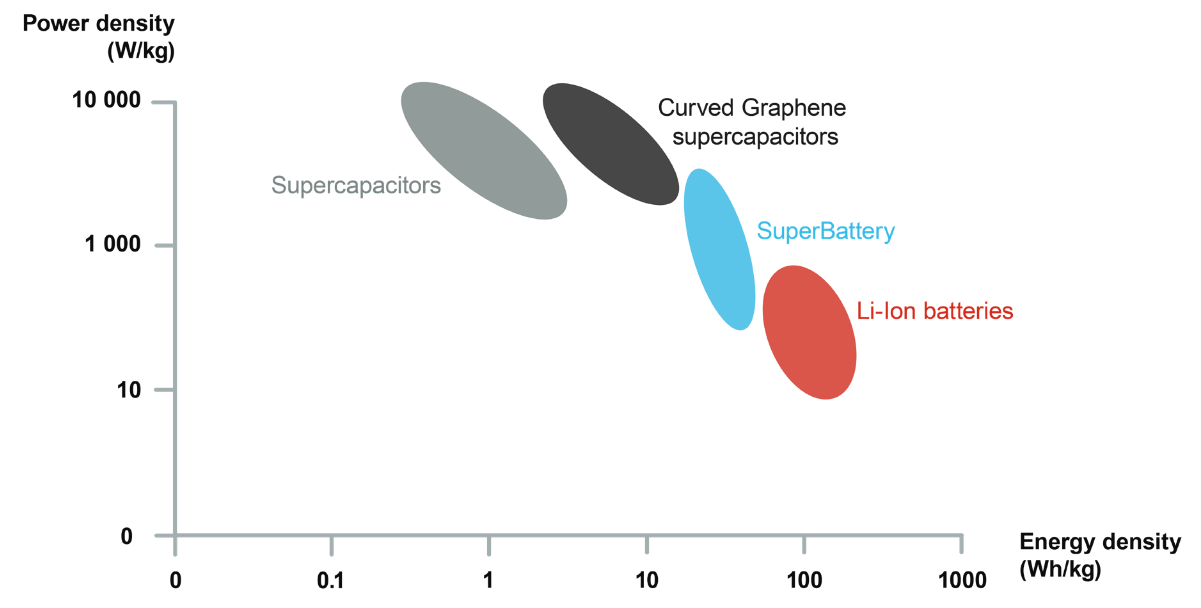

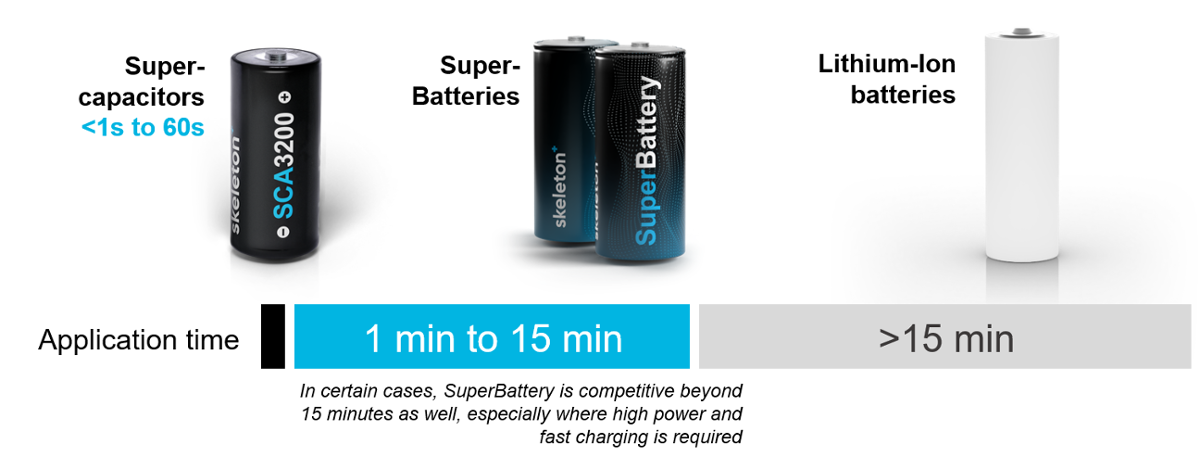

Skeleton has for years been known as the global technology leader in supercapacitors, a technology ideally suited for applications where high power is needed for a short amount of time (up to 60 seconds). In applications where power is needed for a longer time, supercapacitors are generally not the right fit due to their low energy content. On the other hand, most battery chemistries are best for long-term energy storage and perform poorly when subjected to high currents.

There has been a gap in the market: application times from 60 seconds to 15-30 minutes have been problematic as supercapacitors are not able to provide the required amount of energy for such a long time, unless vastly oversized, and therefore out of the price and ideal size and weight range. With batteries, the solution has also been oversizing to reach the necessary power requirements often associated with short-term applications.

SuperBatteries combine the characteristics of supercapacitors and batteries, resulting in a technology offering the best of both worlds:

- Charged in 60 seconds and capable of powering up to 30 minutes of use for example for heavy mining trucks

- Inherently safe - no thermal runaways and no need for thermal propagation measures.

- 50,000 lifecycles - 10-20x the lifetime of lithium-ion batteries

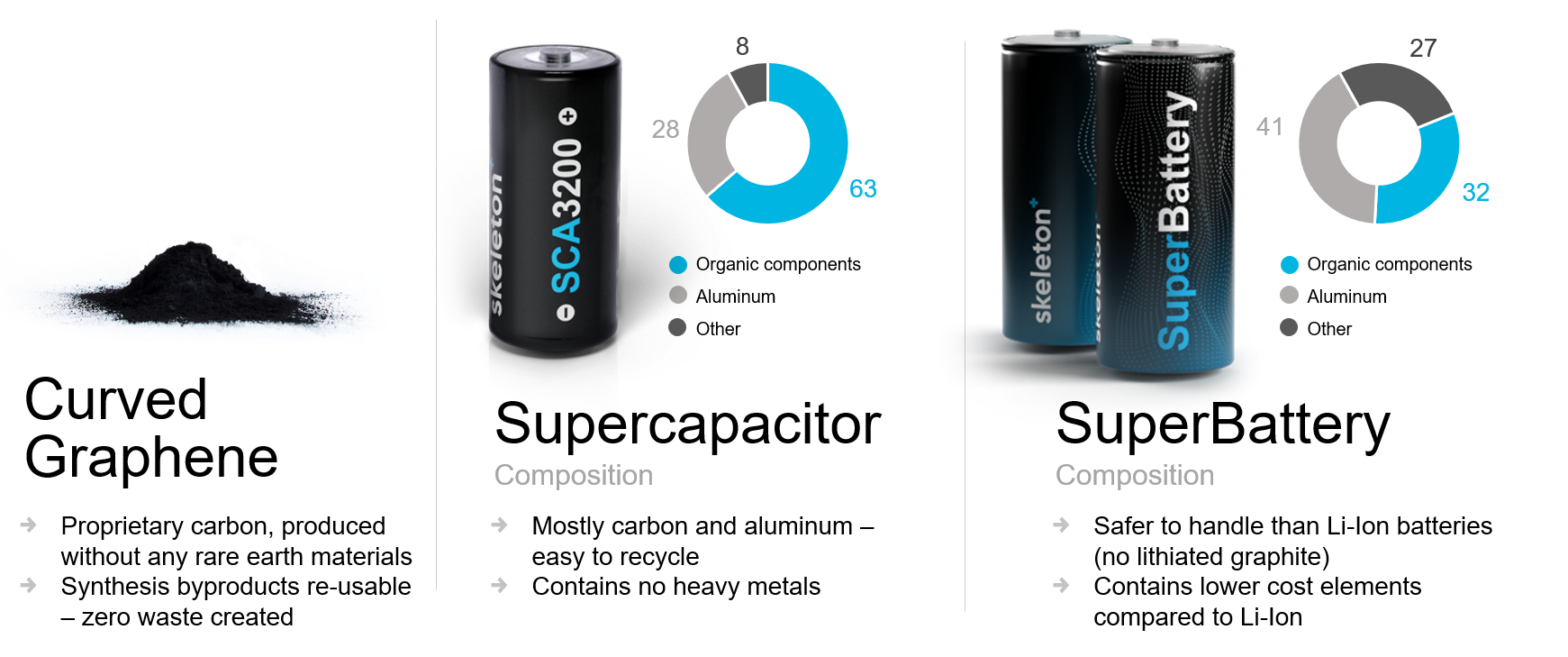

- SuperBatteries do not use any cobalt, nickel, graphite, or copper, and are much easier to recycle than batteries.

SuperBatteries are based on Skeleton's patented Curved Graphene carbon raw material. They are much easier to recycle due to the narrow range of materials used and the minimal number of components in the cell design.

The first SuperBattery product comes in the supercapacitor industry standard D60 large cell form factor, followed by a variety of modules for automotive, transportation, and industrial needs.

Excellent safety - proven by 3rd party testing

Industrial prototypes of SuperBattery cells have been safety tested with excellent results, with five different tests conducted to test the safety of the technology:

- Short-circuiting

- Overcharging

- Crushing

- Nail penetration

- Overheating

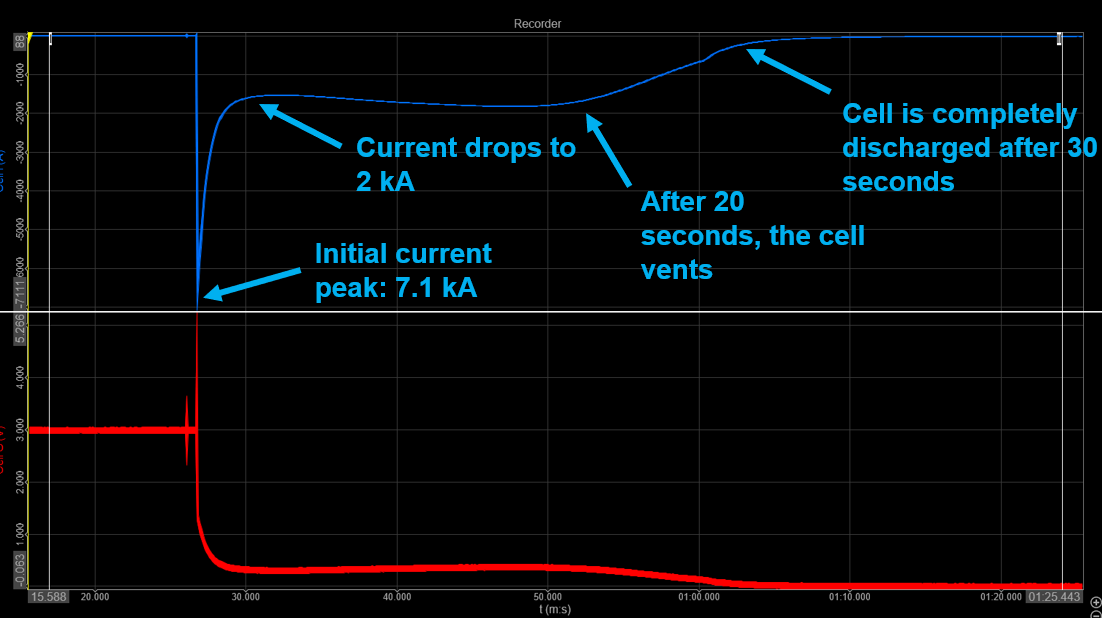

1. Short-circuit through 0.18 mOhm

Recorded peak short-circuit current 7.1 kA. After 2 seconds, the current dropped below 2k and was continuously running through the circuitry for around 30 seconds.

On the image above, you can see the cell voltage (red line) and circuitry current (blue line), showing the short-circuit created on the 26th second of the log. The cell vented after 20 seconds through the safety valve, no fires or explosion occurred.

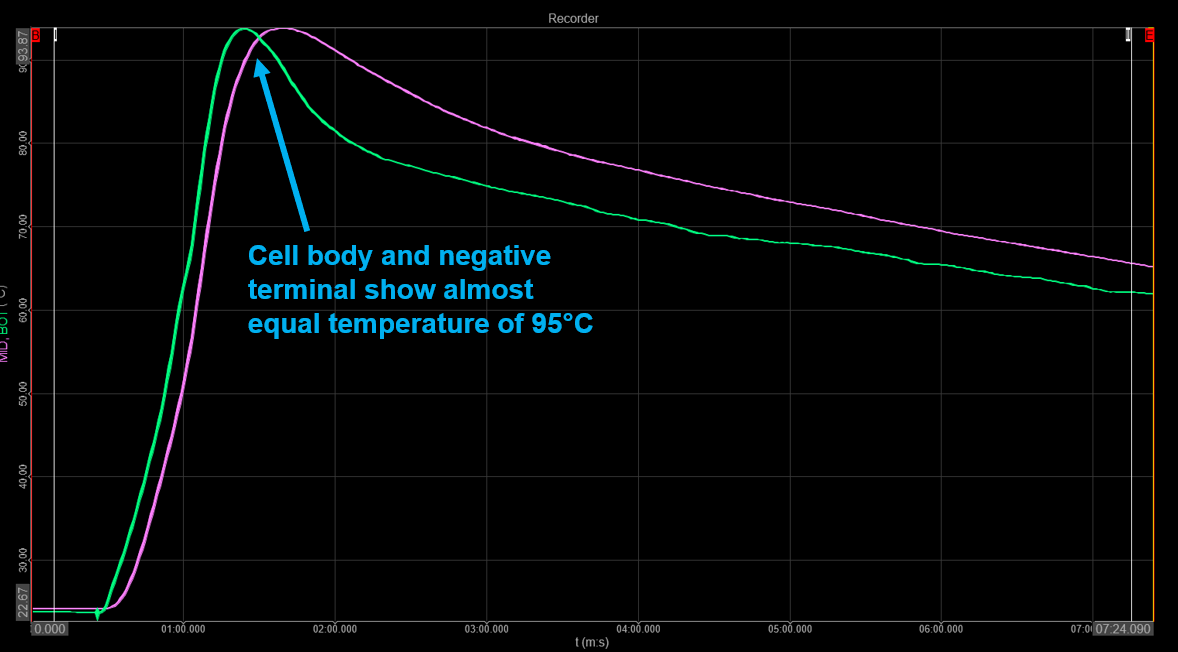

Short-circuiting the SuperBattery caused its temperature to rise to about 95 °C (203 °F), with the graph below showing the cell body temperature as the pink line and the cell negative terminal temperature as the green line.

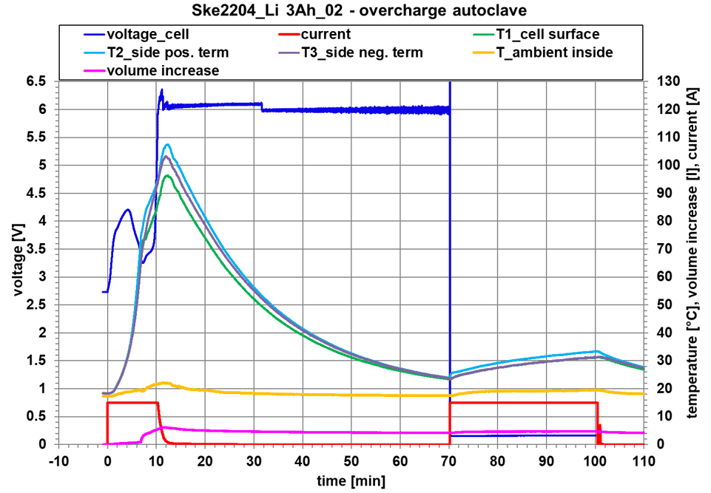

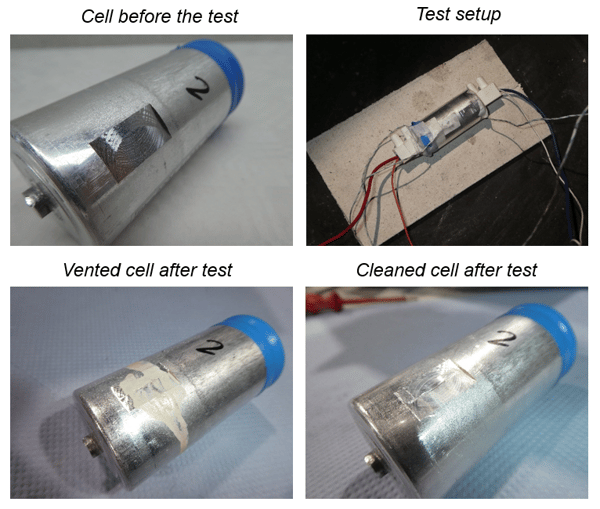

2. Overcharge to 6.0 V (200% rated voltage)

Overcharging the SuperBattery to 200% of its rated voltage gave similar results: the cell vented safely as designed, with no safety risks occurring.

The safety valve is visible on the cell and worked as designed

The safety valve is visible on the cell and worked as designed

throughout the safety testing of the SuperBattery.

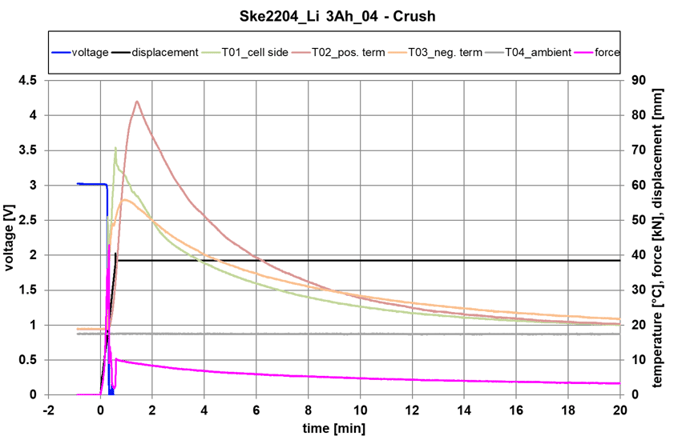

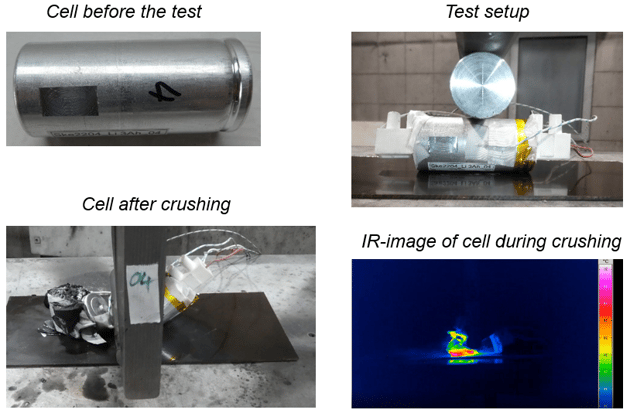

3. Crushing a SuperBattery cell

The 3rd test conducted on the SuperBattery was crushing the cell at a fully charged state (3.0V) with a cylinder (d = 30 mm) at 1 mm/s. The crushing test resulted in the SuperBattery cell deforming entirely, but no fires or explosions occurred.

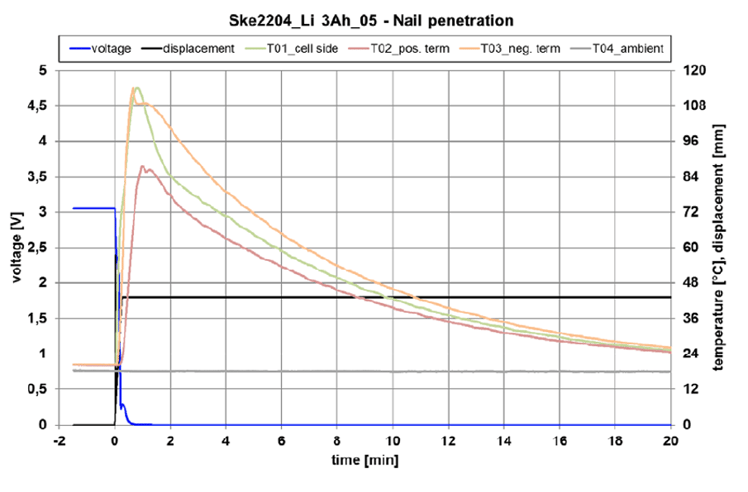

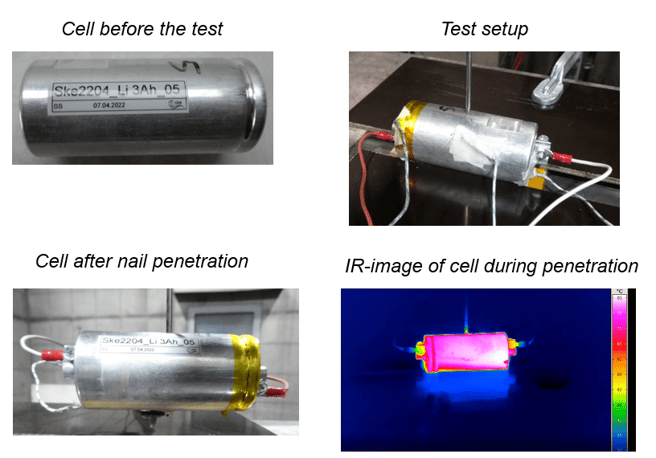

4. Penetrating a SuperBattery cell with a nail

A fully charged (3.0 V) SuperBattery cell was completely penetrated with a nail (d = 3 mm) at 10 mm/s safely, with no fires or explosions occurring.

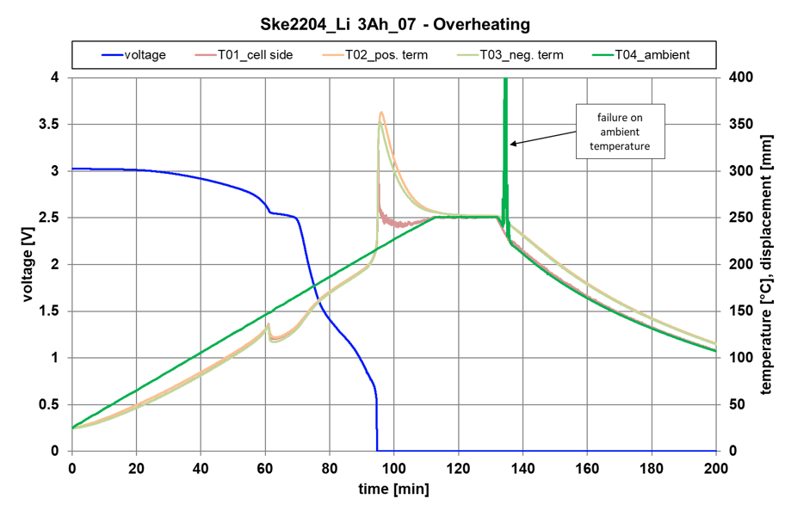

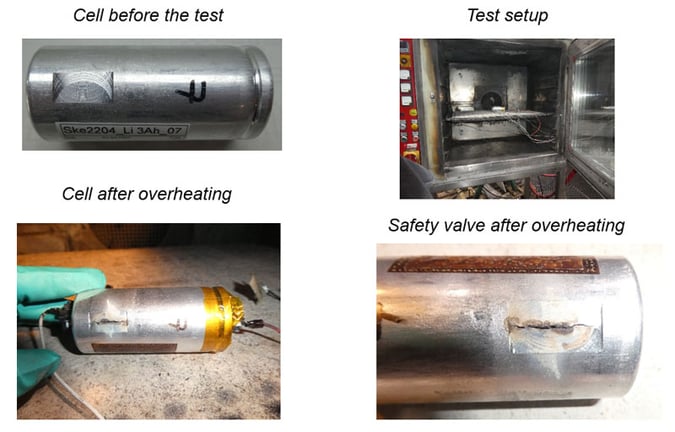

5. Overheating

The last safety test conducted on the SuperBattery was overheating a fully charged (3.0 V) cell to 250 °C (482 °F) in an oven. The safety valve opened at 135 °C (275 °F) with the maximum temperature of the cell reaching 363 °C (685 °F). No fires or explosions occurred, no thermal runaway - no need for thermal propagation measures.

The excellent results in the safety testing mean that SuperBattery energy storage solutions can be used in areas and applications that are deemed too risky for lithium-ion battery cells, for example. In addition, lowered needs for fire propagation prevention measures can result in cost savings.

Applications for SuperBatteries

Our partnership with Shell and the other consortium members on mining electrification is an excellent example of the potential of SuperBattery technology. It can help to completely electrify large mining machinery, starting with diesel-powered haul trucks, enabling decarbonization.

Diesel-powered haul trucks are one of the biggest polluters in mining, burning more than 100 liters of diesel fuel per hour. Electrifying one haul truck is the equivalent of eliminating the yearly CO2 emissions of more than 10,000 passenger cars.

Diesel-powered haul trucks are one of the biggest polluters in mining, burning more than 100 liters of diesel fuel per hour. Electrifying one haul truck is the equivalent of eliminating the yearly CO2 emissions of more than 10,000 passenger cars.

Mining is one of the most challenging industries to tackle when it comes to electrification and decarbonization, but technologies like the SuperBattery are necessary to make it happen.

Beyond mining, our customers are already testing SuperBatteries for passenger cars, for hydrogen fuel cell + SuperBattery hybrid solutions for transportation, and a number of industrial applications where safety, sustainability, and long lifetime are key enablers.

Is SuperBattery a good fit for your application?

Identifying the right energy storage technology can be complicated, which is why Skeleton's application engineering team is always involved in our customer discussions, ensuring both sides have of the requirements of your application and the benefits our supercapacitor and SuperBattery technologies can offer.

To find the ideal energy storage technology for your application, a good starting point is identifying the most challenging part of the application, for example:

- Must be charged within 2 minutes, or

- Must have a lifetime of more than 20 000 charge-discharge cycles

This can already give us enough information to disqualify certain technologies and move the discussion forward. If you are having problems identifying the biggest problem but you already know the energy and power requirements, you can calculate the C-rate:

Maximum power in kW / energy in kWh = C-rate

or

Maximum current in A / capacity in Ah = C-rate

Knowing the C-rate will also help disqualify specific energy storage technologies due to their charge and discharge limitations, helping us to delve deeper into your application requirements to find the best solution for your needs.

The definition of C-rate from Battery University:

Charge and discharge rates of a battery are governed by C-rates. The capacity of a battery is commonly rated at 1C, meaning that a fully charged battery rated at 1Ah should provide 1A for one hour. The same battery discharging at 0.5C should provide 500mA for two hours, and at 2C it delivers 2A for 30 minutes. Losses at fast discharges reduce the discharge time and these losses also affect charge times.

A C-rate of 1C is also known as a one-hour discharge; 0.5C or C/2 is a two-hour discharge and 0.2C or C/5 is a 5-hour discharge. Some high-performance batteries can be charged and discharged above 1C with moderate stress.

Energy storage sizing can be tricky, which is why Skeleton has specialists to do it, and we're happy to work together with your team to find the best match for your application.

Read more about SuperBattery here and get in touch with us to discuss how we can support your company.